On top of its standard products, Yoctopuce proposes to manufacture customized variants to address specific needs from customers. We discussed this in a general way some years ago, but over time we noticed that the initial discussion with a customer interested by a customized version was always the same. So we offer you this week some thoughts on the ins and outs of a customized Yoctopuce module.

On top of its standard products, Yoctopuce proposes to manufacture customized variants to address specific needs from customers. We discussed this in a general way some years ago, but over time we noticed that the initial discussion with a customer interested by a customized version was always the same. So we offer you this week some thoughts on the ins and outs of a customized Yoctopuce module.

Incentives

One of the main incentives to ask for a customized module is the possibility to merge several Yoctopuce modules into a single one. A frequent requirement is the combination of one or several Yocto-Relay with a Yocto-Knob to obtain a module with inputs for buttons and outputs commuted with relays. Merging several modules into one enables the use of a single microcontroller, a single USB connection, a single power supply, and so on, which reduces the costs significatively and simplifies both the assembly and the USB wiring.

Another variant which is of large interest is to put together standard modules and a YoctoHub, which enables you to obtain a module for which the different functions are accessible both through the network and through USB.

Be aware, however, that not all combinations of Yoctopuce modules are necessarily possible. There are limitations: a Yoctopuce modules can host a maximum of 15 functions, including YModule. But the total number of functions can also be limited by the microcontroller memory size, which is quite small. For example, we know for having tried it that one cannot put a wifi feature, an automatic alarm clock, and a GPS on the same module.

Customized modules also help you for mechanical integration: the customer can freely choose the shape of the module, the position of the anchor points, and the connector types.

Form factor and enclosure

It's somewhat counterintuitive, but the first question to ask yourself when you want a custom-made module is how it is going to be integrated on a mechanical standpoint, and more particularly the type of enclosure that you intend to have. This question is essential because it is infinitively easier to design an electronic board that fits into an arbitrary enclosure than to find an enclosure in which you can install an arbitrary board.

The customer can obviously choose to keep using standard Yoctopuce enclosures, but these enclosures are relatively expensive, as we are well aware. Therefore, we rather recommend you to look at enclosure manufacturers whose job it is to manufacture boxes for a competitive price. We often work with Polycase, but there are many others : New Age Enclosures, Hammond, Metcase, Serpac, and so on. All enclosure manufacturers offer a customization service to add openings and decorations on any face. Generally, the final cost for this type of customization is inversely proportional to the ordered quantity. You must expect to order at least a hundred items to obtain a decent price.

The different types of enclosures

There are mainly three types of enclosures.

Classical enclosure with a lid

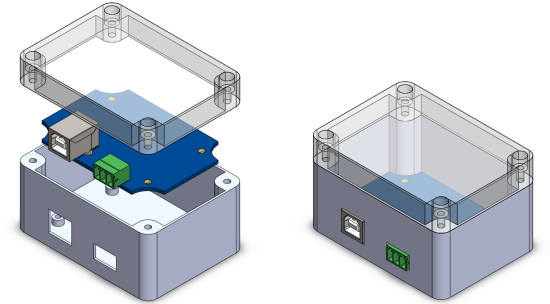

In this case, you screw the module at the bottom of the enclosure. This type of enclosure is often waterproof. If you want to keep it waterproof, we need to make all the wires to through glands. If, on the contrary, you want to create openings to have connectors flush with the outer surface of the enclosure, you can't have connectors on all the sides, otherwise the card won't fit in.

A classic enclosure with lid

The half-shell enclosure

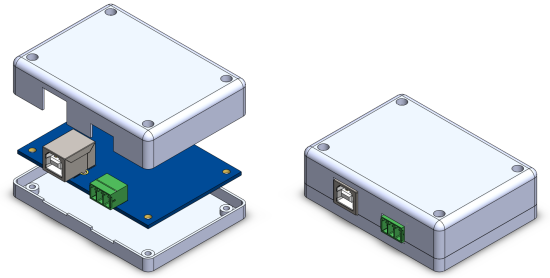

In this case, the board is mounted on the lower side so as to find itself slightly below the joint plane. This enables you to have openings overlapping the joint plane, and therefore connectors on four sides if necessary.

An enclosure in to half-shells

The extruded enclosure

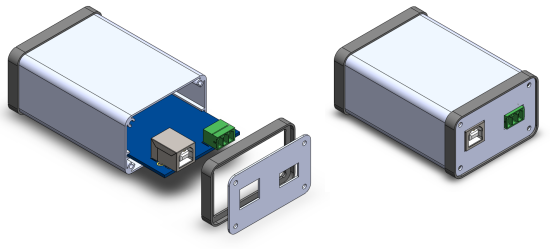

This type of enclosure is made of an extruded body with grooves to slide in the PCB. The faces are directly screwed at each end. As the faces as simple plates, they are quite easy to make yourself with a minimum of tools. This type of enclosures enables you to have connectors at each end, and generally enables you to obtain a rather pretty design at a low cost. However, the faces being usually on the narrow side, the size of the enclosure and thus of the board slid inside increases very quickly with the number of required connectors.

An extruded enclosure

In the case of a enclosure designed for a customized module, Yoctopuce takes care of specifying the necessary modifications directly with the manufacturer and the customer doesn't need to worry about it. However, once the design is validated and technical discussions are over, we prefer for the customer to order the said enclosures directly. Its quite ridiculous to import the enclosures to Switzerland only to export them again to another part of the globe. However, if the customer is keen to have the modules delivered directly mounted in the enclosures, we will take care of this, but we will charge a margin on the enclosures.

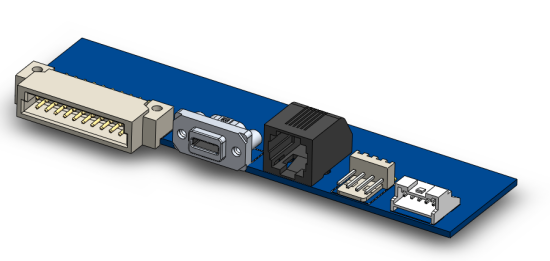

Connectors

Standard Yoctopuce products use micro-USB connectors and screw terminals because it's relatively easy to build and to use. However, there are other choices which can be of interest in some cases.

USB connector

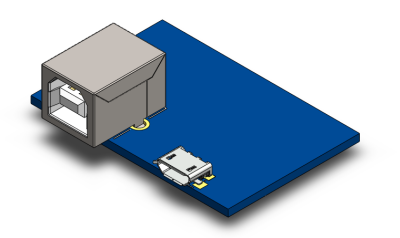

The micro-B USB connectors used in standard Yoctopuce products have a small weakness: being surface mount components, they can be ripped out if you don't take care. Therefore, we recommend to select a USB-B connector, which is more solid for a product which might be installed or used by low-skilled staff.

USB B vs micro-B

Up till now, Yoctopuce never built a module with a USB-C connector and we are not in a hurry to take the plunge: in terms of complexity, these connectors are clearly a big overkill for modules using only USB 1.1.

Input-output

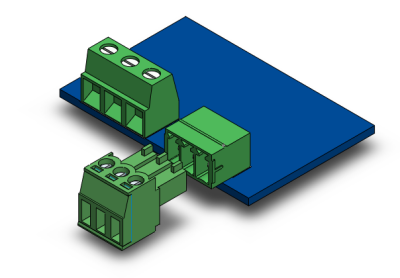

Standard Yoctopuce modules use screw terminals on the boards, but for customized modules we recommend pluggable connectors which make wiring and maintenance a lot easier despite a slightly higher cost.

Simple screw terminals vs pluggable screw connector

By default, we propose these green connectors because we keep large stocks of them. But if the customer wants another one, and if we can buy it in large enough quantities, we happily use it in the project.

We can use any connector, as long as we can buy it

We don't manufacture products with input/output cables directly soldered on the PCB: it's a nightmare to manufacture and to pack.

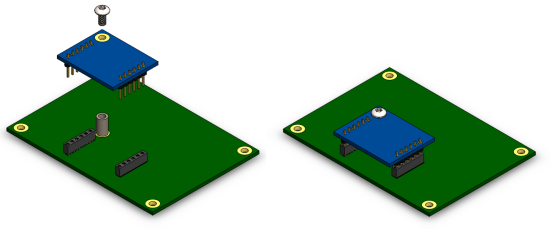

Board to board

If the customer wants to connect Yoctopuce modules to a board for which he has control of the design, there is a solution which is simple, inexpensive, and which saves space: a module as a daughter-board that plugs into the main board using simple headers or other board-to-board connectors, even if it means adding a spacer to lock it in place.

We can also make a simple daughter-board

Prototype

When Yoctopuce and the customer agree on all the technical aspects, a design is submitted, with an estimate for expected costs of the project and the minimal order quantity for production.

If the design and the costs are accepted, the prototype is manufactured and sent to the customer so that he can check that it fulfils all the expectations. This prototype is naturally billed. The prototype price is set more or less arbitrarily depending on the complexity of the project, but generally it is about EUR 250. At this rate, Yoctopuce looses money of the prototypes but each customized project is a bet on the future and it is very seldom that a serious customer renounces to go into production after having tested a prototype.

About betting on the future, know that a customer who never used a Yoctopuce module before who would directly ask for a custom product has a good chance of being politely turned down. Experience shows that projects initiated by customers who appear out of nowhere never come to fruition.

Minimum quantities

For Yoctopuce, there isn't a big difference between manufacturing a batch of standard modules or a batch of customized modules. The batch must simply be large enough to be cost-effective. Therefore, there is a minimum quantity for orders of customized products. This minimum quantity is linked to the PCB price which decreases quite fast with ordered quantities. Therefore the minimum order quantity is usually the number of modules that you can fit on 10 plates of about 250x150mm, usually we get a number between 100 and 300.

Timeframe, costs and benefits

For customized products, Yoctopuce doesn't bill any additional costs, no application fees, no design fees, no tooling fees, no photocopying fees, nothing. The price of a custom module is computed exactly like the cost of a standard module: depending on the ordered quantity, between 2.25 and 3 times the cost in components + PCB. However, Yoctopuce requires advance paiement for the prototype and for the production batches. You'll understand that we can't afford to have a customer change his mind once we've started the production process.

The time needed to manufacture a prototype is about 3 weeks and the time needed for production is about 4 weeks. If you add a week to discuss the technical details needed for the prototype, a motivated customer can see the production modules sent to him in 8 weeks.

For the customer, the interest is obviously the possibility to obtain modules that exactly fit his needs in quite modest quantities, without having to invest more than the prototype cost. In fact, it often happens that a custom module ends up being much cheaper than its equivalent in standard modules because we use only one CPU, one power supply, one USB port, and so on.

But the customer is not the only one to benefit. The interest for Yoctopuce is to be able to manufacture a batch of products and to sell it in one go. And if the customer has to order again a batch of his modules at regular intervals, and this happens frequently, it makes regular income for Yoctopuce, which is always good to take.

Confidentiality, exclusivity, and intellectual property

Like everything that concerns Yoctopuce customers, customized products are confidential and exclusive. If someone tried to order a customized product made for another customer, or simply asked us for information about this product, he would be turned down. Some customers sometimes ask us not to put our brand on the PCB of the products that we manufacture for them. In itself, this is not an issue, but you must however know that by design, it is hard to hide the origin of a Yoctopuce product. Even without any particular indication, any software programmer worth his salt will take less than 10 minutes to solve the mystery.

Finally, we want you to know that, even in case of customized products, we sell finished products and not a design service. The design of Yoctopuce products, customized or not, remains the property of Yoctopuce. Design files, manufacturing data, and firmware source code are considered as trade secrets and are not communicated to the customers.

Conclusion

The Yoctopuce team sincerely thinks that the possibility to obtain customized variants of standard products at a similar price, with no other constraint than a minimal order, is an excellent deal for customers. For Yoctopuce, from the marketing standpoint, it doesn't change much: a customized product is a product like the others, except that it's sold to only one customer.