![]() If you are using double-width Yoctopuce modules, you are also familiar with the double-width enclosures. At 18 CHF (excl. tax) each, you probably find them overpriced. So do we. But we had to increase their price significantly. And we think the least we can do is to explain why.

If you are using double-width Yoctopuce modules, you are also familiar with the double-width enclosures. At 18 CHF (excl. tax) each, you probably find them overpriced. So do we. But we had to increase their price significantly. And we think the least we can do is to explain why.

This enclosure is going to cost even more

2012

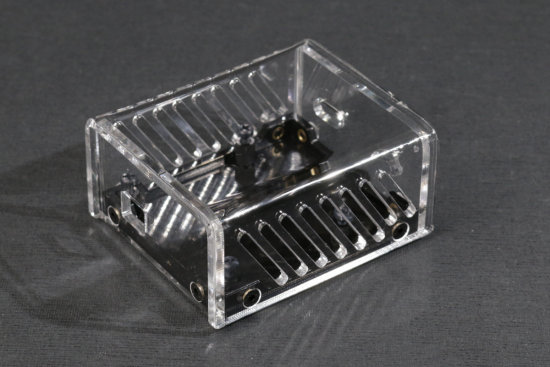

These enclosures came out in 2012 with the first double-width modules. Our experience with single-width modules had taught us that it was imperative to offer our customers enclosures that fit our products. We also knew that we would never be able to afford the molds to manufacture all the possible enclosure variations in injected plastic. We therefore imagined these enclosures composed of a base on which are screwed the faces and the lid, which is a simple plate folded in a U shape. The bases were built with 5 pieces of plastic with threaded inserts and glued together.

A 2012 model base, the pieces are glued together

A price of 18 Swiss francs was calculated by adding the costs of raw material, labor, plus a tiny margin.

2015

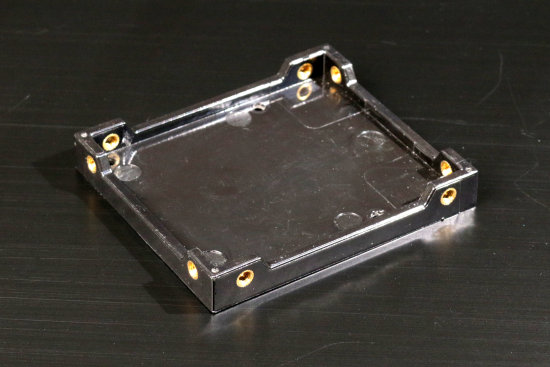

In 2015, as sales increased, we had to face the fact that it was no longer reasonable to spend all that time installing inserts and gluing pieces of plastic to build these bases. Remember that our main activity, the one that makes us live, is to design and build electronic circuits. So we designed an injected plastic base with integrated threaded inserts and had it produced by the ProtoLab company in the UK. This supplier has the advantage of being willing to produce small series without charging exorbitant tooling costs for this item, which is more complicated to mold than it looks.

One of the bases produced in 2015

Obviously, at the time, we redid our computations and we noticed that the cost of the injected plastic base was eating into our margin, but we decided to keep the price at 18 francs, which already seemed very expensive.

Of course, year after year, our raw material costs have increased by small percentages here and there.

2023

And here we are in 2023, we have just placed and paid for an order for a new batch of bases whose cost has, like everything else, gone up. So we decided to recalculate what these boxes are really costing us, taking into account everything that is quantifiable.

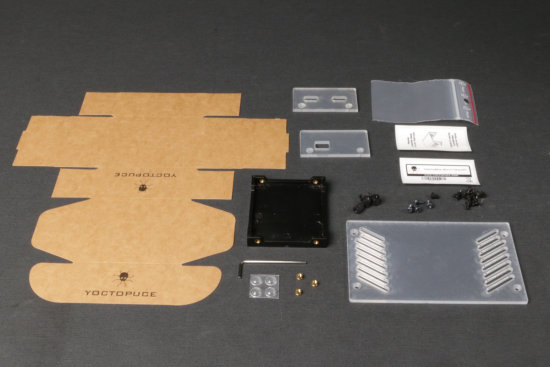

Here are all the elements of a double-width enclosure, how much do you think it costs?

Apart from the base, which is extremely expensive, each element only costs on average about ten cents, but when you add it up, the result is a bit frightening.

| Description | Quantity | Manufacturer / distributor | Cost in 2015 | Cost in 2023 |

|---|---|---|---|---|

| base | 1 | Protolabs (UK) | 7.830 | 9.104 |

| threaded insert | 11 | Bossard / Hasler (CH) | 0.913 | 0.977 |

| countersunk screw | 12 | SFS (CH) | 1.056 | 2.364 |

| lid | 1.2dm2 | Vink (CH) | 0.480 | 0.922 |

| face | 2x0.28dm2 | Vink (CH) | 0.224 | 0.402 |

| plastic spacer (PEEK) | 4 | Essentra | 0.950 | |

| plastic spacer (PEEK) | 4 | EFP industries (FR) | 1.491 | |

| plastic screw (PPS) | 4 | Aliexpress (CN) | 0.372 | |

| plastic screw (PEEK) | 4 | EFP industries (FR) | 1.118 | |

| feet | 4 | 3M / mouser.com (EU) | 0.195 | 0.259 |

| allen key | 1 | Holex / SFS (CH) | 0.200 | 0.379 |

| cardboard box | 1 | Shallow Moon (CN) | 0.401 | 0.365 |

| label | 2 | Brother / Digitec (CH) | 0.033 | 0.048 |

| bag | 1 | Rajapack (CH) | 0.092 | 0.108 |

| labor | 5m 42s | Yoctopuce | 5.710 | 5.710 |

| Total (CHF) | 18.46 | 23.25 |

Some explanations to help you understand some lines:

Threaded inserts

We counted 11 inserts per case when a base contains only 8, because Protolabs asks us to send them a ratio of 11/8 inserts for each batch. We imagine that the complexity of molding causes a significant failure rate, we never managed to get a clear explanation about this.

Area calculations

The raw material area calculations are based on the number of lids and faces that can fit on a 600x300mm plate.

Screws and plastic spacers

The calculation example given is the Yocto-Watt enclosure. For safety reasons, some of the screws are made of a special plastic (PEEK or PPS) which, in addition to being non-conductive, is more heat resistant than ordinary plastic. The spacers were originally ordered from Essentra who eventually stopped producing them, the screws were ordered, more or less happily, on AliExpress. We finally found a French company, EFP Industries, to sell us equivalent screws and spacers made in Europe.

Labor

We calculated that it takes an average of 5 minutes and 42 seconds of manual labor to build and pack a double-width case. This time does not include the cutting time which is done by a CNC machine. In the early days of Yoctopuce, we computed that each hour of manual labor had to directly or indirectly bring in at least 60 Swiss francs into Yoctopuce's coffers to start being profitable, hence the estimated labor cost of 5.71 CHF.

Shipping costs

In this calculation of production costs, we are missing some shipping costs that we could not trace, so the real result is probably a few tens of cents higher in both columns.

Conclusion

We have reached a point where the selling price hardly covers the cost of raw materials, so we had to adjust the price of the double-width enclosures from 18 to 24 Swiss francs (excl. tax), which is an increase of 33% over eleven years. Hopefully, we won't have to change it for several years. We're sorry it's come to this, but we can't really afford to sell products at a loss. That said, no one ever claimed that you had to buy these cases, with a little ingenuity you could even do without them.