Among the various requests that you have made to us, there is one which is particularly difficult to satisfy: to provide an enclosure to protect and dress our modules. Sure, we could have contented ourselves to sell a grey plastic container in the purest 70's style, as others do it, but this really didn't fit with the style of the modules. We could have gone for an acrylic glass enclosure, which has always a good rendering on pictures, but it would have been too bulky and unpractical with regards to the size of our modules. No, something better was needed, something which would not make our modules lose their size advantage...

Among the various requests that you have made to us, there is one which is particularly difficult to satisfy: to provide an enclosure to protect and dress our modules. Sure, we could have contented ourselves to sell a grey plastic container in the purest 70's style, as others do it, but this really didn't fit with the style of the modules. We could have gone for an acrylic glass enclosure, which has always a good rendering on pictures, but it would have been too bulky and unpractical with regards to the size of our modules. No, something better was needed, something which would not make our modules lose their size advantage...

Therefore, we went ahead with the only solution which enabled us to obtain a small, truly adapted, practical, robust, and presentable enclosure: a tailored enclosure made of injected plastic. We won't hide from you that we are taking a risk: we need to sell several thousands enclosures before recovering the initial investment...

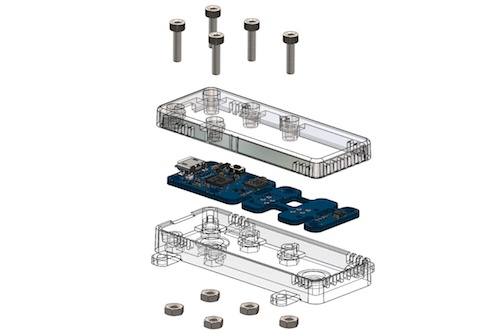

We designed the enclosure ourselves entirely, trying to anticipate the different use scenarios. We have planned four distinct methods to fix the enclosure to a support:

- four small breakable brackets, which can hold mini screws

- two conic locations at the bottom of the enclosure, for hidden screws

- two magnets which fit in the bottom of the enclosure, for removable fixing

- double-sided tape, for provisional fixing in a hurry

The enclosure itself can be closed with 5 small nuts embedded in the base, shutting up the module in place.

our project of mini-enclosure for our tiny USB modules

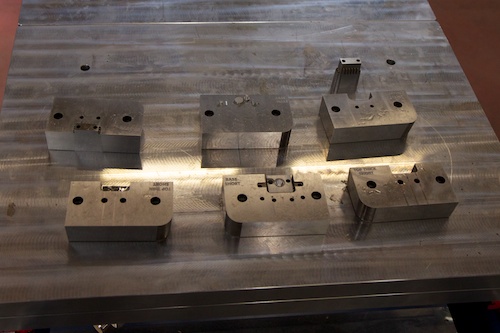

When we had a design which we liked and a few prototypes printed in 3D, we went to meet plastics technicians who informed us of constraints on the mold which we didn't know before: drafts, ejectors, and so on. After some discussions and modifications to the design to enable molding and mold ejection, and to accommodate several enclosure sizes, we broke our piggy-bank and ordered the mold. Here is the result (it is made in France):

a few parts from the mold

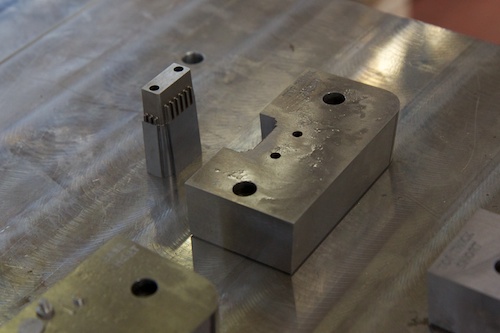

close-up on a mold insert (the strips will create the vents)

For the plastic material, we selected:

- for the cover, an acrylic glass, which we can cut and personalize afterwards with a laser

- for the base, alternatively: either a transparent polycarbonate, or a black ABS.

For temperature sensors, we also provide a base in a thermoconductor plastic, in order to help evacuate the heat from the processor and thus to better the measures.

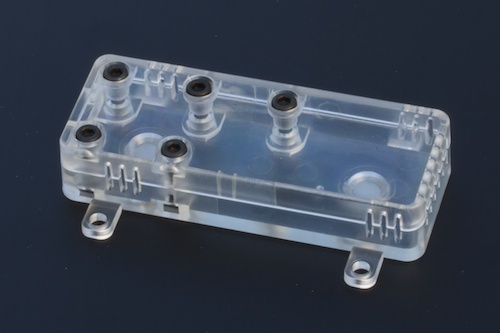

As a preview, here are the first enclosures:

the awaited first enclosures coming out of the press

As soon as all the enclosures are off the press and we have written the documentation, you'll find these enclosures for sale in our shop. Because we have produced these enclosures in the optic of valorizing our USB modules, we have decided to make them as accessible as possible and therefore to sell them at cost price. The selling price will thus depend on the final bill from the plastics technician, but it should be around EUR 9.- for most sizes.

To wrap up, for those who, like us, did not yet see a plastic injection factory and are curious to see how such a machine works:

| Injection of the first enclosures for Yoctopuce USB modules, in Kaneco factory (France) | ||