![]() A customer asked us how to detect whether a washing machine is working or not. The first idea that comes to mind is to measure its consumption with a Yocto-Watt, but there are ways of doing things more subtly for less money.

A customer asked us how to detect whether a washing machine is working or not. The first idea that comes to mind is to measure its consumption with a Yocto-Watt, but there are ways of doing things more subtly for less money.

The problem is quite simple: you just want to know whether a mains-operated appliance is working or not. But we're not allowed to modify the device itself. Rather than measuring the actual consumption of the appliance, the idea is to use a current transformer to estimate the amount of current flowing through one of the wires carrying electricity to the appliance.

Current transformers

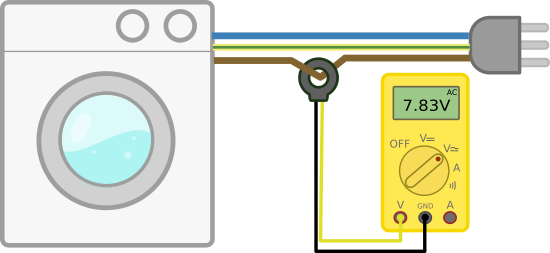

Presented like that, a current transformer looks big, heavy and expensive, but in fact it's just a little ring-shaped coil you can buy for next to nothing. All you have to do is pass one of the supply wires through the ring, and the alternating current flowing through the wire induces an alternating voltage across the coil, which you can measure to get an idea of the current flowing through the wire in question.

Using a current transformer to estimate the current (AC) flowing through an electrical wire

To test how this works, we chose model 1243896 sold by RS-PRO, which is less than 2 cm in diameter and costs just a few euros. This coil is specified for 25A, which is more than sufficient for our purposes.

The RS-PRO 1243896 coil

DIY version

We also wondered, since it looks so simple, if we couldn't make one ourselves. All you have to do is wrap some electrical wire around a toroid made of ferromagnetic material. So we patiently wound about 2 meters of 0.2mm wire around a 7x12x5mm toroid (inner diameter x outer diameter x thickness). We don't know exactly what this toroid is made of, just that it's normally used to filter the long wires of RC model servos.

Our hand-made coil, the toroid comes from a servo cable

Honestly, it's time-consuming and tedious to build, and the result isn't nearly as smooth as we'd hoped. You're clearly better off spending a few euros on a ready-made one, and using the time you save to build something more interesting.

Test protocol

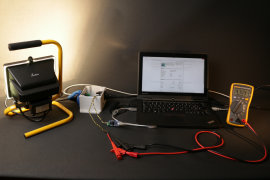

To check that it works properly, we used an electrical box in which a Yocto-Watt is installed. We ran one of the wires from the internal wiring through our two coils. The idea is to measure the voltage across the two coils and compare it with the Yocto-Watt measures.

So we used this box to power a few large consumers we had on hand.

| Device | Power (W) | Current (A) | RS-PRO coil (V AC) | DIY Coil (V AC) |

|---|---|---|---|---|

| Nothing | 0 | 0 | 0 | 0 |

| Induction hob (standby) | 7 | 0.6 | 1.93 | 0.13 |

| Halogen spotlight | 417 | 1.7 | 4.70 | 0.20 |

| Vacuum cleaner | 1250 | 5.5 | 6.34 | 0.14 |

| Induction hob (on) | 1200 | 6.4 | 7.31 | 0.20 |

| Kettle | 1650 | 7 | 7.58 | 0.20 |

| Heat scraper | 1700 | 7.2 | 7.57 | 0.20 |

| Saper + kettle | 3200 | 14 | 8.52 | 0.24 |

It works really well, with a perfect distinction between a device on standby and one in operation. However, the voltages at the terminals of the two coils are clearly not directly proportional to the current: the higher the current, the flatter the curve. Our home-made coil works, but compared with the RS-PRO version, it doesn't look like much.

What about the washing machine?

To answer our customer's question, we finally used our box during a 60░C washing machine cycle. We connected the RS-PRO coil to a Yocto-Volt and used Yocto-Visualization to see what happened.

A complete wash cycle

The cycle lasts around 3 hours, and the results are quite clear: you can see the different phases of the washing machine's operation quite clearly:

- When the machine is "off", it consumes 15W (!) and the coil voltage is around 0.1V.

- When the machine is on, but on standby, it consumes around 25W and the coil is at 0.4V

- When a wash cycle is in progress, consumption varies between 60 and 2000W, but there are phases during which, every 22 seconds, there is a pause of about one second when consumption drops to 15W. Coil voltage, meanwhile, varies between 2.6 and 7.8V, with the same pauses when the voltage drops to 0.15V.

- At the end of the cycle, the machine switches off, power drops to 15W and coil voltage is around 0.1V.

Note that the machine consumes around 2000W during the first 30 minutes of the cycle, probably to heat the water. During this heating time, the temperature of the Yocto-Watt rises to 45░C, which could cause concern if it were installed in an airtight enclosure.

So the answer to our customer's question is: with the model of machine used for the test, if the voltage at the terminals of our coil is below 1V for more than a few seconds, the machine stopped.

Limitations

This current transformer-based detection solution is extremely easy to implement, but there are a few limitations to be aware of:

- It only works with alternating current.

- The coil voltage is also AC, so you need a device capable of measuring AC voltage.

- The coil voltage is not necessarily linear with the current.

- Even if you manage to linearize your values, you won't be able to deduce your device's actual power consumption. In alternating current, instantaneous power is not simply current times voltage. It also depends on the offset between voltage and current. This offset, more or less pronounced, is induced by inductive loads, typically anything containing windings: coils, motors, transformers, solenoids, and so on, which may be found in your appliances.

Conclusion

If you just need to detect whether a mains-powered appliance is running or not, a Yocto-Volt and a current transformer are far more interesting than a Yocto-Watt:

- There's no risk of overheating.

- The measuring electronics don't interact directly with the circuit to be measured.

- It's easy to install.

- It's compact.

- It's less expensive than a Yocto-Watt.