This week we made a test bench for a torque wrench. We used a Yocto-Bridge with a static torque sensor.

This week we made a test bench for a torque wrench. We used a Yocto-Bridge with a static torque sensor.

A torque wrench is a wrench that measures the torque applied. This tool helps avoid under-tightening (which can lead to loose parts) or over-tightening (which can damage threads or parts).

They are frequently found in bicycle mechanics, where many parts are made of carbon or aluminum. The price of these wrenches varies widely, depending on the measuring range and the type of technology used.

A few torque wrenches

In theory, these wrenches should be recalibrated every year or after 5000 cycles. In practice, very few bicycle mechanics perform this calibration. Bicycle mechanics being relatively simple, we generally look for an order of magnitude rather than absolute precision. In fact, most torque wrenches are roughly graduated.

As some Yoctopuce employees are keen cyclists, we looked into the possibility of setting up a test bench to check these torque wrenches and check that they haven't gone out of adjustment over the years.

Building the test bench

To build this test bench, we used a static torque sensor and a Yocto-Bridge.

The static torque sensor

A static torque sensor relies on a load cell to evaluate the torque exerted. Unlike a scale, which measures pressure, this cell detects the torsion applied to the load cell axis. Its principle is similar to that of a conventional load cell, but instead of indicating a force in grams, it provides a torque measure expressed in Newton-meters (Nm).

We chose an inexpensive torque sensor which can measure a maximum torque of 50 Nm in the tightening direction.

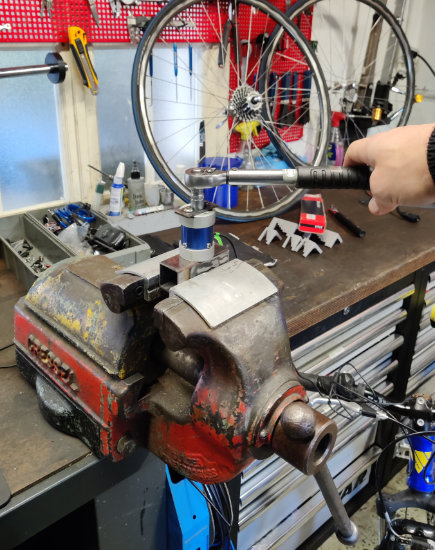

We made an adaptor to fit a bolt to the end of the transducer. We made this adapter from scrap metal, to which we welded an M6 nut with a 10mm hexagonal head. This dummy bolt is secured with 2 M5 bolts.

The other end of the torque sensor is screwed onto a square tube which enables the installation to be secured in a vice or on a table.

The torque sensor with the adapter

Once everything is assembled, we can fix our test bench in a vice or on a table using a clamp and simulate tightening the false bolt with the wrenches.

The test bench assembled

Yocto-Bridge configuration

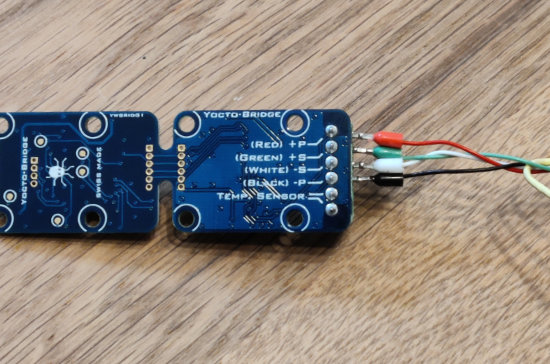

Now it's time to connect the sensor to the Yocto-Bridge and to configure it. In our case, the connection is trivial, as the torque sensor uses the standard color code for load cells. These colors are marked on the back of the Yocto-Bridge, so all you have to do is connect each wire to the corresponding terminal block.

For once, the connection is trivial

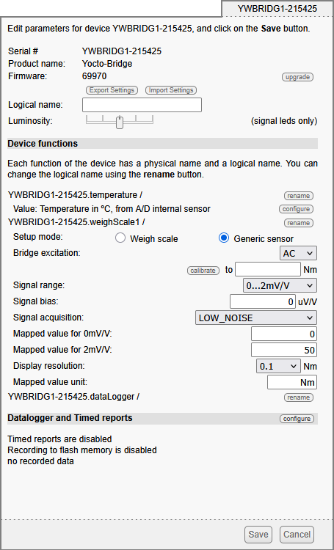

Before checking our torque wrenches, we need to configure the Yocto-Bridge with the torque sensor parameters. To do this, use VirtualHub to access the Yocto-Bridge configuration panel.

Switch the module to "Generic sensor" and activate AC excitation so that the Yocto-Bridge starts interacting with the sensor. For other parameters, use the torque sensor specs:

- Signal range : 0...2mV/V

- Mapped value for 0mV/V: 0 Nm

- Mapped value for 0mV/V: 50 Nm

- Unit: Nm

The Yocto-Bridge configuration parameters

Once these parameters have been saved, the Yocto-Bridge measures the torque applied to the bolt. We can check that the values are read correctly in the VirtualHub interface, or use any other software that works with our sensors.

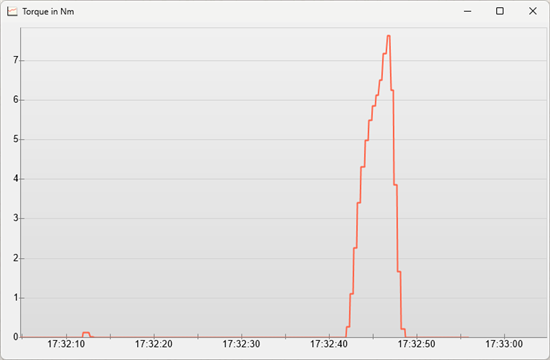

In our case, we used our Yocto-Visualization software, which can graph any Yoctopuce sensor.

For example, here's a graph of a torque wrench set to 8 Nm.

The graph of a measure with a 8 Nm trigger

Conclusion

This test bench is a simple and economical way of checking torque wrenches. The inexpensive sensor we used is sufficient for our purposes, but it's no substitute for proper calibration by a measurement institute. This test bench enables you to check that your wrenches are working properly and, above all, to compare them with one another.