At Yoctopuce, we electronically send the information of all our packages, whether it is the content or the weight. For the later, we use a USB scale which is limited to a weight of 10 Kg. To overcome this limitation, we are going to test several types of scales, with a Yoctopuce sauce of course.

At Yoctopuce, we electronically send the information of all our packages, whether it is the content or the weight. For the later, we use a USB scale which is limited to a weight of 10 Kg. To overcome this limitation, we are going to test several types of scales, with a Yoctopuce sauce of course.

Types of scale

As a first step, we must look at the different types of scales and decide which ones can be useful in our situation There are two main types of scales: the tray scale and the hanging scale.

A tray scale and a hanging scale

The hanging scale is mechanically easy but it is not mobile. It is also very complex to use, because it needs many ropes to hold the package, or it must have a platform large enough to contain the packages. The swing due to its suspension may slightly distort the measures. The tray system is more adapted to our needs, it is more mobile, it takes less room, and it is very stable. There are still some mechanical issues, as we will see below.

Implementing the scales

To make a tray scale, you must use one or several load cells. We decided to use AL6N-C3-30kg-3B6 cells from VARIOHM, they support 30Kg each. For our tests, we built two scales: one with a single cell which is placed at the center of a plate and a second with four load cell which are located on each side of the plate. Having several cells enables us to be more stable and to support a heavier weight.

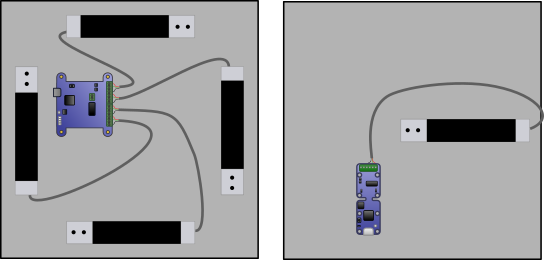

Four cell scale and single cell scale

Obviously, we are going to use Yoctopuce module to read the cell measures: the Yocto-Bridge for the single cell scale and the Yocto-MaxiBridge for the four cell scale because it has four inputs.

Configuring the scales

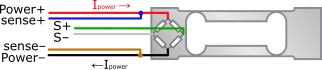

As we are using our own modules, we have four inputs in the Yocto-Bridge and twelve in the Yocto-MaxiBridge. However, each cell has 6 wires and we must therefore minimize the number of wires used. Fortunately, "sense" wires are directly connected to the power supply, so we can leave aside the blue and black wires.

Wiring the AL6N-C3-30kg-3B6 cell

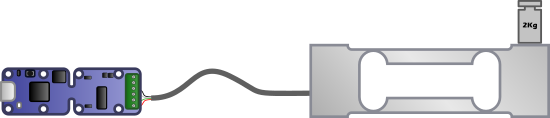

When the wiring is done, we test the load cells one after the other with the VirtualHub and a 2Kg weight. The VirtualHub has a function to tare to zero and a function to calibrate a predetermined weight. We tare a first time to zero, then we set the 2 Kg weight and we calibrate on the VirtualHub the weight on the cell. Then we simply remove the weight and we tare a second time to zero, then we set the 2 Kg weight down again. If the cell correctly indicates the weight, we can remove it and check if the scale goes back to zero without the weight. The cell is tested and ready to use. For a four cell scale, we must repeat this operation for each cell separately.

Cell being tested

The VirtualHub interface

Assembling the tray and testing the scale

To complete the assembly and have a loading zone, we screw a tray on the cells and we tare to zero so as not to measure the tray in the measured weight. We test this time the cell reaction with regards to loading zones, by setting the weights at different locations on the loading zone.

Our two test scales

The single cell scale measures the weight perfectly, no matter where the weight is located on the scale. The four cell scale has more important mechanical constraints and is more easily disturbed by the deformation of the tray. The displayed weight is less accurate because the displayed value results from a computation between the four cells. To calibrate the four cells, you must remove the loading zone and adjust them one after the other to tare them and set the cells to zero. The single cell scale is much easier to reset to zero, as the displayed value is the measured value, without computation.

Selecting the scale

This brings us to the point where we need to decide which scale to use to weigh the large packages to be sent. Although it is limited to 30Kg, the single cell scale is much more appropriate because it is much easier to reset to zero if its settings are perturbed. Moreover, we very rarely have packages heavier than 25 Kg, it is therefore perfect for our use.

The big winner