![]() Quite a while ago, we offered you a a brief soldering tutorial. Given the success of this post, we thought that you'd perhaps like us to explain how to desolder an electronic component without losing your mind...

Quite a while ago, we offered you a a brief soldering tutorial. Given the success of this post, we thought that you'd perhaps like us to explain how to desolder an electronic component without losing your mind...

If you have already tried to desolder a component, you know the issue: a component is generally fixed to the PCB with several contacts and it is difficult to melt the solder on all the contacts at the same time. Solder cools down too fast to try to heat each contact one after the other.

Naturally, there are work stations dedicated to component desoldering. But if you have one, your line of work is probably about electronic boards rework, and so you won't be much interested by the remainder of this post. Therefore, we are rather going to concentrate on methods available to ordinary people.

In fact, there are many techniques to remove an electronic component from a PCB. Here are the best known:

Brutal: the heat gun

A very simple technique consists in using a heat gun to heat the area where the component is located. After a few seconds, you can easily remove the component. This technique is not very sophisticated as it tends to desolder all the components located in the area. However, it is very efficient to desolder QFN type components that have a central pad soldered on the PCB.

Heat gun: very efficient but unselective

Surgical: the desoldering tweezers

Desoldering tweezers are a small pincer of which the ends are in fact two tiny soldering irons. You only have to pinch the component that you want to desolder with the tweezers. This tool is extremely effective for all the two pole SMD components: resistors, capacitors, diodes, and so on...

For components with few legs

With some ability, you can even use it to remove some small components of type SOT23, TSSOP, and so on... If you haven't set the tweezers temperature too high, you can even reuse the components.

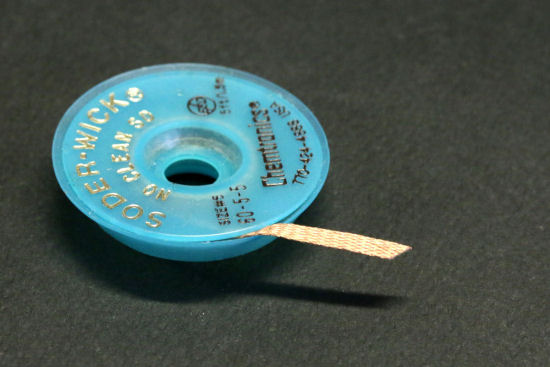

Cheap: the desoldering braid

A desoldering braid is made of very thin copper wires braided together. Cover your solder with flux, put the end of the braid on it, and delicately press with the tip of a warm soldering iron. Solder melts and is absorbed into the braid by capillarity. It's a useful method for through hole components. However, it doesn't work very well with surface components as there is always some solder which prefers to stay between the component and the PCB.

Desoldering braid: convenient and cheap

Mechanical: the desoldering pump

A desoldering pump is a kind of spring syringe: you arm it by pushing the piston. By pressing a button, the piston is violently pulled back, creating a suction. The idea is to melt the solder and to aspirate it with the pump. This tool is sometimes efficient for through hole components, sometimes less so. Frankly, it's not the technique we prefer.

Desoldering pump: a questionable effectiveness

Messy: compressed air

If you don't have a desoldering pump, but have compressed air available, you can use the opposite technique which consists in heating each leg and in expelling the melted solder with a good blast of compressed air. It is very effective and you can reuse the component afterwards. However, you are going to have solder projections everywhere. Take care to protect the remainder of your PCB and the surrounding area before you try it.

Compressed air: very efficient but messy

Sharp: cutting pliers

To remove a component from a PCB, the most practical method is to cut each leg with very thin and sharp cutting pliers. You can then remove the component and desolder the legs one after the other. Obviously, it works only if your component has legs. The component is destroyed in the process.

Cutting pliers, very thin and sharp

For this kind of work, the best cutting pliers that we found so far are sold by a well-known model making brand.

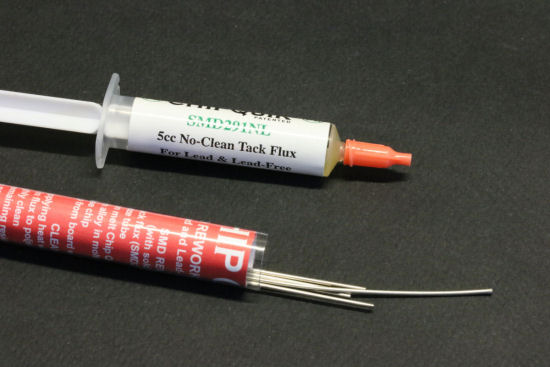

Magical: Chipquik

We saved the best for the end. The ChipQuik company commercializes a product enabling you to desolder most components easily. At first sight, the "SMD removal" kit is nothing more than soldering wire with a flux syringe. But this is not ordinary wire: it's an alloy which is specific in that it melts at a low temperature and remains liquid for a very long time.

Chip Quik: a magical product

To desolder a component with this product, put a generous lump of the provided flux on the legs and melt the alloy on each of the legs. The alloy mixes itself with the original solder, and the whole can stay liquid for a good ten seconds. If you work fast enough, you can easily remove the component. You can usually reuse the component afterwards.

Equivalent competing products may exist but, if it is the case, we never heard of them.

Cleaning up

When you have desoldered your component, you find yourself with a not so clean PCB. Pads are covered with solder and flux remains, which makes it harder to place a new component. You must therefore clean the pads. To do so, the simplest way is to use a desoldering braid to remove solder, and then one of these products designed to remove flux remains.

Flux cleaner

Conclusion

If you occasionally need to desolder a component, you don't need to invest into expensive equipment. Some basic tools and some dexterity enable you to get out of most situations. This video summarizes the different techniques described in this post.

Finally, you must know that some components, on top of being soldered, are also glued. This makes them harder to remove. For Yoctopuce products, this concerns terminal blocks. If you need a module without terminal block, simply ask for the module to be delivered without terminal block, rather than trying to desolder it yourself.