Summer will be back in a week, and with it comes the sausage season! Obviously, geeks won't barbecue in the sun, everybody knows that the sun provokes cancers and it's dangerous for your health. So, how can you cook a hot dog sausage at the office, without putting fire to it, and without any other equipment than the few Yocto-modules lying about? Ideally, we'd like to monitor the cooking by USB, if it isn't too much to ask...

Summer will be back in a week, and with it comes the sausage season! Obviously, geeks won't barbecue in the sun, everybody knows that the sun provokes cancers and it's dangerous for your health. So, how can you cook a hot dog sausage at the office, without putting fire to it, and without any other equipment than the few Yocto-modules lying about? Ideally, we'd like to monitor the cooking by USB, if it isn't too much to ask...

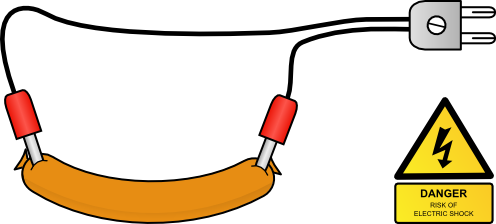

The solution is an old physics student trick: you make a large dose of electricity go through the sausage. As the sausage is a poor conductor, this heats it. For the basic version, you don't need to be nit-picky: a hot dog sausage has the correct resistance to be directly connected to the 220V of the mains, without any further ceremony:

Sausage cooking with 220 V, low-tech version. Caution, high risk of electrocution !

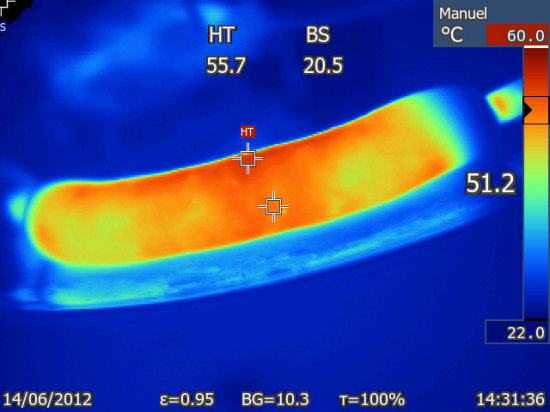

It's devilishly effective: your sausage is ready in 15 seconds. It's probably even green: almost no energy lost, and no grey energy spent in a sophisticated household appliance (which we don't have at the office in any case). This method has only two drawbacks: The first one is that if you touch the sausage to check its cooking while it's switched on, you die. The second is that, like all very fast cooking modes (such as microwave ovens, etc.), this method tends to irregularly heat the sausage because heat doesn't have time to propagate itself. Moreover, as the resistance of the sausage gets lower as the sausage warms up, more and more power goes through, generating more and more heat. This problem gets worse as the sausage becomes warmer.

Infrared picture of a sausage with current going through

Fortunately, the Yocto-modules are here to provide a technological solution to sausage issues.

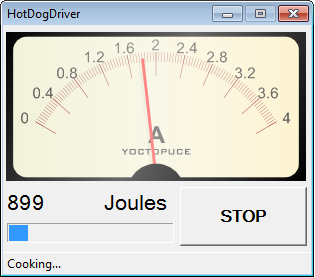

Let's look at the problem in a more scientific way. If we make the assumption that a sausage behaves more or less like salted water, to heat it by 1 degree, you must feed it one calorie per gram of sausage (it's the definition of a calorie). Therefore we would need about 2000 calories to heat by 40 degrees a 50g sausage. But what are 2000 calories? It's about 8400 Joules, so for examples 600 Watts during 14 seconds. To summarize, to control the cooking of a sausage, we only need to count the watts per second which go through the wire. It's a safer way than to touch the sausage.

To count the watts, we are going to mount a Yocto-Amp in series with the sausage, measure how many watts go though it at every instant, and compute this way the transmitted energy by adding these values for each fraction of a second. The Yocto-Amp is not properly speaking a wattmeter for alternating current (because it does not compute the instant product of the voltage and the current), but in the present case, as we know that the voltage of the mains is stable and that the sausage is not an inductive load, we can allow ourselves to simply multiply the AC current given by the Yocto-Amp by 235 VAC to obtain the power in Watts dissipated in the sausage.

To even out the temperature in the sausage, we are going to use the same process as in microwave ovens: alternate short heating impulsions and waiting periods to let the heat propagate itself. A Yocto-PowerRelay is ideal for this. At the same time, we can afford to dynamically adapt the duration of the heating impulsions depending on the quantity of energy transmitted to the sausage, and thus take into account the decrease in sausage resistance during the cooking.

Here is a schema of the final installation, with a color led on top to warn the user when the installation is switched on:

The appliance to cook hot dog sausages in a lab, Yoctopuce version

The relay is used for cooking control only, it doesn't make the installation safer. Indeed one of the wires connected to the sausage is also permanently connected to the mains. We still need to disconnect the installation before handling the sausage.

The implementation itself requires only 10 minutes, a Yocto-PowerRelay, a Yocto-Amp, and a Yocto-Color, all of these mounted on a FixPlate-X3.

The same, for real

The control software is written in C#. It is a simple variant of the sample program in C# provided for the Yocto-Amp.

Control software for cooking sausages

And to prove that we are not having you on, the video of the action!

Obviously, it's a particularly dangerous project. If you want to try it, do not do it alone and be extremely careful, we'd like to keep our customers :-)